Advanced Engineering & Extensive Equipment

– Technician Training

Our in-house assistance program for earning certifications provides full-ranging support so employees can get spring technician certifications and other qualifications. In doing so, we value

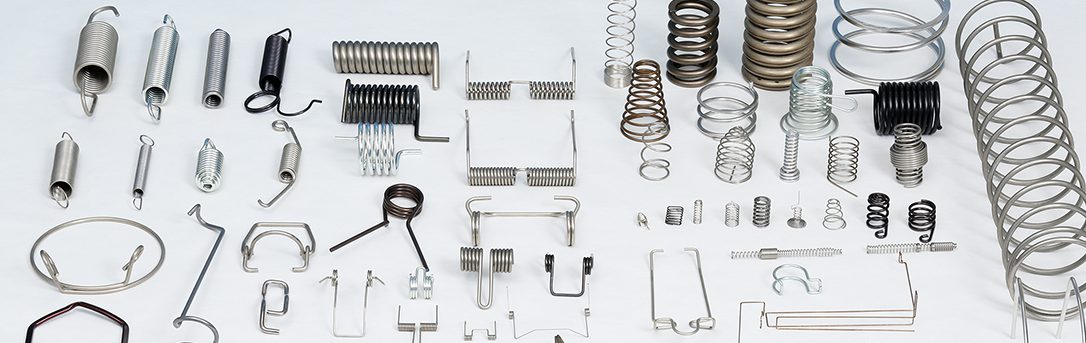

– Versatile Equipment

We possess a diverse range of equipment including progressive presses, spring coiling machines, forming machines, safety valve assemblers for batteries and other parts, machine tools, and more.

– 1st in Industry to Install Latest German-Made Equipment

Our facilities are equipped with four CNC coiling and bending machines built by Wafios AG. These latest FMU series models range in size from 16 to 40. They handle complex fabrication of springs, precision item prototyping, and mass production. FMU16 (21 axes) FMU25 (21 axes) FMU32 (22 axes) FMU40 (21 axes) Aoi Spring is the only company in Japan to have four of the latest FMU series models by Wafios.

– Jigs and Tools Built In-House

At Aoi Spring, we make our own tools, jigs and inspection jigs for springs and other products. That allows us to leverage unique, innovative ideas to perform complex fabrication and get the finished products to you quickly.

– Cost reductions from fully automated production

- Dimension correction with cameras and sensors inside equipment

- Direct links with secondary equipment including automated product collectors and tempering devices

- Part dispensers to assemblers, automatic inspection devices

– We can handle special materials

hastelloys, monel, inconel, nickel, titanium, etc.

– Contract fabrication orders

We also take many contract fabrication orders from other companies in our industry.

Integrated Support System

When it comes to manufacturing springs, you can leave everything to Aoi Spring. Our adaptability allows us to handle everything from single-item and small-lot production to mass production of a million units a month.

From spring design to lifetime calculation—we can help you.

If you have a sample or existing product, we can take precision measurements to produce drawings with CAD. We can also check drawings you may already have.

If you provide us with the part you need to pair with a spring, we can promptly create a prototype spring for evaluation.

Even if all you have is a hand-drawn picture, we can still offer a proposal.

Beginning in the development phase, we offer ideas for spring longevity, material, shape, surface treatment, and cost reduction.

Prototyping with mass production equipment enables a smooth transition to full-scale production. We provide solutions in the prototyping stage to save you the hassle of finding a supplier for mass production.

Thorough Quality Assurance

In 2003, we obtained the ISO 9001 certification and built a new quality control system to ensure compliance with the stringent quality control requirements from the battery industry, auto parts manufacturers, and other customers.

- A proven track record in mass production for auto parts makers in Japan and abroad

- Ability to handle stringent quality control requirements for in-vehicle parts, including PPAP, FMEA, SPC management, CPK management, etc.

- Traceability system using shipping dates and lot numbers to track production history, material lots, etc.

- 4M (men, machines, materials, methods) change management

- Use of original shipment inspection software

We maintain a database of shipment inspection results, which we use to raise quality by applying statistical techniques such as Xbar-R management charts, histograms, CPK, etc. - Complete testing regimen

- Enhanced testing equipment installed for each production and quality check process

- Testing jigs further boost inspection accuracy

- Inspections performed on all products requested

- Checks for non-conformity, foreign substances, and residual materials; routine inspections on product dimensions, appearance, etc

60 Years of Experience and Results

Since Aoi Spring’s inception in Higashiosaka in March 1953, our primary business in spring production has been complemented by manufacturing assistance for makers in diverse sectors including batteries (secondary batteries, fuel cells), automotive parts, home appliances, medical devices, agricultural machinery, and residential equipment.

Meanwhile, we export to customers in Southeast Asia, Europe and elsewhere beyond Japan, and are an approved mass-production plant for European automotive parts makers.

Backed by the experience and expertise amassed over 60 years of close cooperation with major manufacturers, we are able to offer the following:

- Over 10 years in ISO 9001/14001 operations

- EDI order servicing

- Introduction of production control systems

- Quality and environmental auditing (electric machinery makers, automotive parts makers)

- Environmental chemical substance surveys (Rohs, etc.)

- Training to help spring technicians obtain professional certification, etc.

A proven track record distinguished with numerous subsidies and awards:

- 2014: Excellent Company of Osaka, special prize

- 2016: Selected as one of 300 Vibrant Habataku Small and Medium Enterprises by the Ministry of Economy, Trade and Industry

- 2018: President Takaaki Aoto received the Order of the Rising Sun (6th Class Silver Rays) in the autumn

- 2013-2017: Received the Monozukuri Subsidy five years in a row